MGMN-M type blade, cvd chemical coating professional processing steel parts material

Product Details

With the continuous deep research of material technology, the company can provide high-performance, high-strength of different specifications of various types of cemented carbide bars, cemented carbide plates, electronic specifications boards, non-standard shaped materials, cold block die, wire drawing die, powder metallurgy die, CNC blade and so on.

### MGMN-M type blade, CVD chemical coating professional processing steel materials

In today's highly industrialized era, precision machining technology has become one of the indispensable core competitiveness of the manufacturing industry. Among many processing tools, high-performance cutting inserts have become the first choice for processing steel materials due to their excellent efficiency and durability. Among them, the MGMN-M blade, with its unique CVD (chemical vapor deposition) chemical coating technology, is in the field of steel processing, showing extraordinary processing capacity and stability.

#### Introduction: Why Choose MGMN-M Blades

In the field of metal cutting, the choice of materials is directly related to the processing efficiency, tool life and processing quality. As one of the most common processing materials, the hardness, toughness and thermal conductivity of steel parts put forward strict requirements for cutting tools. MGMN-M type blade, as a series of blades specially designed for steel processing, through the introduction of advanced CVD chemical coating technology, effectively solves the problems of easy wear and poor heat resistance of traditional blades in the processing process, and becomes a sharp tool to improve the processing efficiency and precision.

#### CVD Chemical Coatings: Crystallization of Technological Innovation

CVD chemical vapor deposition is an advanced process for forming a solid film on the surface of a material through a chemical reaction. In the production of MGMN-M blades, this technology is subtly applied to the production of coatings. By precisely controlling the reaction conditions, such as temperature, pressure and gas flow, high hardness, high wear resistance, high corrosion resistance compounds (such as titanium carbide, aluminum titanium nitride, etc.) are uniformly deposited on the surface of the blade substrate to form a layer of dense and strong bonding force. This coating not only significantly improves the hardness and wear resistance of the blade, but also enhances its thermal shock resistance and oxidation resistance, so that the blade can maintain stable cutting performance under high temperature, high speed and high load cutting environment.

#### Advantages of professional processing of steel materials

1. **Improve processing efficiency**: With its excellent wear resistance and sharp cutting edges, MGMN-M blades can easily cope with the cutting of steel materials, reduce cutting force and reduce energy consumption, thereby significantly improving processing efficiency. At the same time, its good self-sharpening ability ensures that the cutting edge remains sharp for a long time, reduces the number of tool changes, and further improves production efficiency.

2. **Extended tool life**:CVD chemical coating provides an additional protective barrier for MGMN-M-type inserts, effectively resisting wear and corrosion during cutting, and significantly extending tool life. This not only reduces production costs, but also reduces downtime caused by frequent tool changes and improves the overall efficiency of the production line.

3. **Ensure processing quality**: Stable cutting performance and excellent surface quality are another highlight of MGMN-M blades in steel processing. The high hardness and low friction coefficient of the coating reduce the generation of cutting heat and cutting force, reduce the roughness of the workpiece surface, improve the machining accuracy and surface quality, and meet the needs of modern manufacturing for high quality products.

4. **Strong adaptability**: The MGMN-M blade has been carefully designed and can be widely used in the processing of various steel materials, including but not limited to carbon steel, alloy steel, stainless steel, etc. Its excellent versatility and adaptability make it an ideal choice for many manufacturing enterprises.

#### Conclusion: Future Outlook

With the development of manufacturing industry in the direction of intelligence and precision, the requirements for processing tools are getting higher and higher. MGMN-M type blade, with its unique CVD chemical coating technology and excellent performance, in the field of steel processing has shown a strong competitiveness. In the future, with the continuous progress and innovation of technology, we have reason to believe that MGMN-M blades will play their unique advantages in more fields and contribute to the high-quality development of the manufacturing industry. At the same time, this will also encourage more companies to devote themselves to the development and production of cutting tools, and jointly promote the progress and prosperity of the entire industry.

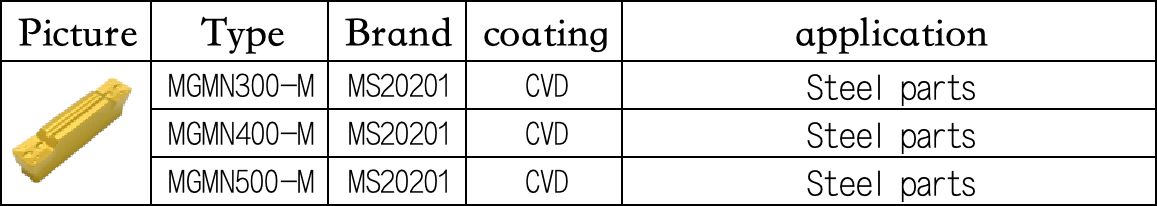

| Type | Brand | coating | application |

| MGMN300-M | MS20201 | CVD | Steel parts |

| MGMN400-M | MS20201 | CVD | Steel parts |

| MGMN500-M | MS20201 | CVD | Steel parts |

Keywords: MGMN-M type blade, cvd chemical coating professional processing steel parts material