Grinding grade MGGN grooving blade processing steel parts, stainless steel

Time:2024-10-16

### Grinding grade MGGN grooving blade processing steel parts, stainless steel

In the field of metal processing, with the continuous progress of material science and the increasing requirements of precision and efficiency in industrial manufacturing, the development and application of high-performance cutting tools are particularly important. Among them, the grinding grade MGGN grooving insert with its excellent cutting performance, durability and machining accuracy, in the processing of steel and stainless steel and other hard materials show extraordinary strength. This paper will deeply discuss the characteristics, processing advantages and specific application of grinding grade MGGN grooving insert in steel and stainless steel processing.

#### 1. Grinding Grade MGGN Grooving Blade Overview

MGGN grooving inserts, as a member of high-end cutting tools, the "MGGN" in its name often represents a specific material combination or coating technology, which is designed to improve the hardness, wear resistance, thermal crack resistance and lubrication performance of the insert. The grinding level emphasizes that the blade is processed by a precise grinding process to ensure that the sharpness of the cutting edge, the accuracy of the geometric shape and the surface roughness reach a very high standard to meet the high-precision processing requirements under complex working conditions.

#### 2. the unique advantages of MGGN grooving blade

1. **Excellent wear resistance**:MGGN material combined with advanced coating technology, effectively resist the wear generated in the process of processing, prolong the service life of the blade, reduce the frequency of tool change, improve production efficiency.

2. **Excellent thermal crack resistance**: In the cutting environment of high temperature and high pressure, MGGN blade can maintain stable physical properties, reduce cracks caused by thermal stress, and ensure the safety and stability of the processing process.

3. **High-precision machined surface**: The precision-ground cutting edge can ensure that the machined workpiece has high surface finish and high dimensional accuracy, meeting the needs of precision manufacturing.

4. **Wide applicability**: Whether it is difficult to process materials such as low alloy steel, high carbon steel or stainless steel, MGGN grooving inserts can show good cutting performance and strong adaptability.

#### Application Practice of 3. Processing Steel Parts

As one of the most common materials in mechanical manufacturing, the processing quality of steel directly affects the final performance of the product. When machining steel parts with grinding grade MGGN grooving inserts, due to the high hardness and wear resistance of the inserts, it can easily cope with the high hardness and toughness of steel parts, reduce cutting resistance and improve cutting efficiency. At the same time, good thermal cracking resistance ensures that the blade is not easily damaged during continuous processing, and ensures the stability and continuity of the processing process. In addition, the high-precision edge design makes the surface quality of the processed steel parts excellent, reduces the need for subsequent polishing and other processes, and further improves production efficiency.

#### Challenges and Solutions for 4. Machining Stainless Steel

Stainless steel has been widely used in many industries for its excellent corrosion resistance and aesthetics, but its high hardness, high toughness and cutting heat easily generated during processing have brought great challenges to processing. Grinding grade MGGN grooving blade through its unique material formula and coating technology, effectively solve these problems. On the one hand, the high hardness of the blade material can easily cut into the stainless steel, reducing the cutting force; on the other hand, the coating technology reduces the impact of cutting heat on the blade, reduces the sticking phenomenon, and ensures the smooth cutting process. In addition, aiming at the problem of hardening layer easily produced in stainless steel processing, MGGN insert realizes low stress cutting by optimizing cutting parameters and tool geometry, which effectively suppresses the generation of hardening layer and improves the processing quality.

#### 5. epilogue

In summary, the grinding grade MGGN grooving insert with its excellent cutting performance, durability and high-precision processing ability, in the processing of steel and stainless steel and other hard materials show a significant advantage. It not only improves production efficiency and reduces production costs, but also meets the needs of modern industry for high-precision and high-quality processing. With the continuous advancement of technology and the in-depth expansion of applications, it is believed that MGGN grooving blades will play an important role in more fields and promote the development of the metal processing industry to a higher level.

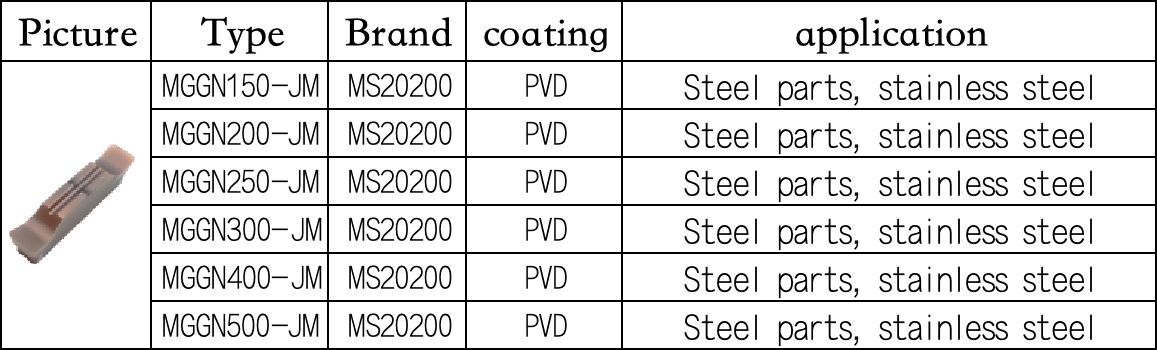

| Type | Brand | coating | application |

| MGGN150-JM | MS20200 | PVD | Steel parts, stainless steel |

| MGGN200-JM | MS20200 | PVD | Steel parts, stainless steel |

| MGGN250-JM | MS20200 | PVD | Steel parts, stainless steel |

| MGGN300-JM | MS20200 | PVD | Steel parts, stainless steel |

| MGGN400-JM | MS20200 | PVD | Steel parts, stainless steel |

| MGGN500-JM | MS20200 | PVD | Steel parts, stainless steel |

Keywords: Grinding grade MGGN grooving blade processing steel parts, stainless steel

Related Cases

-

Lianxiang's professionalism is well-known

An excellent enterprise can give customers a good experience regardless of pre-sale, sale, and after-sale. Lianxiang is like this, which can not only help target customers design excellent mold solutions, but also actively cooperate with the sale, not to mention after-sales service. The service attitude is consistent, praise one!

-

Lianxiang's degree of cooperation is high, and I am very relieved

In the industry, Lianxiang has a strong production scale capacity, a large inventory of raw materials, a high degree of cooperation with customers, and can actively cooperate in the formulated production cycle to ensure on-time delivery, which I appreciate very much, and will continue to cooperate in the future.

-

Lianxiang has the ability to design independently, which I appreciate

Chengdu Lianxiang can not only provide OEM production services according to customer requirements, but also provide design concepts according to the characteristics of our company's products, which makes me feel very relieved. Because I'm more detail-oriented and perfectionist, I always follow my own ideas and don't take into account other aspects. I appreciate that Beder has such an excellent mold design team.