Grinding grade cutting edge MGGNR/L-8, suitable for cutting and processing of steel and stainless steel

Time:2024-10-16

### Grinding grade cutting edge MGGNR/L-8, suitable for cutting and processing of steel parts and stainless steel

In the field of metal processing, the choice of cutting tools directly affects the production efficiency, processing accuracy and material utilization. With the continuous advancement of industrial technology, the demand for high-precision and high-efficiency processing is increasing, especially when dealing with hard materials such as steel and stainless steel, a high-quality cutting tool is particularly important. Today, we will discuss in depth how the outstanding performance of MGGNR/L-8, a grinding grade cutting tool designed for steel and stainless steel cutting, can help modern manufacturing to new heights.

#### Introduction

In metal cutting operations, the quality of the cutting edge of the tool is directly related to the size of the cutting force, the length of tool life and the quality of the machined surface. MGGNR/L-8 as a well-designed grinding grade cutting edge tool, with its unique manufacturing process, excellent material selection and precise geometric design, stands out among many similar products, becoming a leader in the field of steel and stainless steel processing.

#### Tool characteristics analysis

**1. Grinding grade cutting edge technology * *

The core advantage of MGGNR/L-8 is its advanced grinding level cutting edge technology. Compared with traditional cutting tools, the grinding grade cutting edge ensures the sharpness and flatness of the cutting edge to the extreme through the fine grinding process, reducing the friction and resistance in the cutting process, thus greatly improving the cutting efficiency. At the same time, this process also enhances the durability of the cutting edge, prolongs the service life of the tool, and reduces the production cost.

**2. High quality material construction * *

The main material of the tool is one of the key factors affecting its performance. MGGNR/L-8 uses high-strength, high-wear-resistant alloy steel as the base material, and the heat treatment process is optimized to ensure that the tool can maintain stable hardness and toughness in high-speed and high-temperature cutting environments. In addition, in view of the characteristics of difficult-to-machine materials such as stainless steel, the tool also incorporates specific anti-corrosion elements, which effectively prevents the corrosion problem in the cutting process and ensures the smooth progress of the machining process.

**3. Accurate geometric design * *

The geometric design of the MGGNR/L-8 has been precisely calculated and simulated to achieve the best cutting results. Its unique blade angle design not only optimizes the flow path of the chips, reduces the fluctuation of the cutting force, but also improves the smoothness of the machined surface. At the same time, the reasonable tool rake angle, back angle and blade inclination configuration ensure that the tool can be cut quickly and smoothly when cutting into the material, reducing the vibration and wear of the tool, and further improving the machining accuracy and efficiency.

#### Application areas and advantages

**Application areas * *

MGGNR/L-8 cutting tools are widely used in automobile manufacturing, aerospace, machinery manufacturing, mold processing and other industries, especially in dealing with high hardness, high strength steel and stainless steel materials, its performance is particularly outstanding. Whether it is pipe cutting, plate cutting or finishing of parts, it can achieve efficient and accurate processing results.

**Summary of advantages * *

-**High-efficiency cutting**: Grinding grade edge technology reduces cutting resistance and increases cutting speed.

-**Long life**: The combination of high-quality materials and heat treatment process extends the service life of the tool.

-**High precision**: Precise geometric design ensures high surface finish and high dimensional accuracy.

-**Multi-field application**: Widely used in various metal processing scenarios to meet the needs of different industries.

-**Economic and environmental protection**: Reduce production costs, reduce the frequency of tool replacement, in line with the concept of green production.

#### Conclusion

In summary, MGGNR/L-8 grinding grade cutting edge tool with its excellent performance and a wide range of applications, in the steel and stainless steel cutting processing has shown a strong competitiveness. It not only improves production efficiency and reduces production costs, but also promotes the progress and innovation of processing technology. With the increasing demand for high quality and efficient processing in the manufacturing industry, MGGNR/L-8 will undoubtedly become the first choice for more companies to jointly promote the prosperity and development of the metal processing industry.

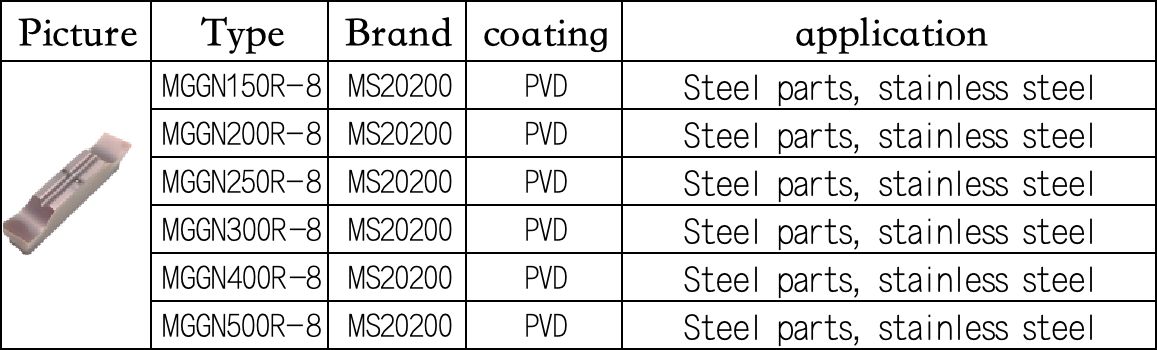

| Type | Brand | coating | application |

| MGGN150R-8 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN200R-8 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN250R-8 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN300R-8 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN400R-8 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN500R-8 | MS20200 | PVD | Steel parts, stainless steel |

Keywords: Grinding grade cutting edge MGGNR/L-8, suitable for cutting and processing of steel and stainless steel

Related Cases

-

Lianxiang's professionalism is well-known

An excellent enterprise can give customers a good experience regardless of pre-sale, sale, and after-sale. Lianxiang is like this, which can not only help target customers design excellent mold solutions, but also actively cooperate with the sale, not to mention after-sales service. The service attitude is consistent, praise one!

-

Lianxiang's degree of cooperation is high, and I am very relieved

In the industry, Lianxiang has a strong production scale capacity, a large inventory of raw materials, a high degree of cooperation with customers, and can actively cooperate in the formulated production cycle to ensure on-time delivery, which I appreciate very much, and will continue to cooperate in the future.

-

Lianxiang has the ability to design independently, which I appreciate

Chengdu Lianxiang can not only provide OEM production services according to customer requirements, but also provide design concepts according to the characteristics of our company's products, which makes me feel very relieved. Because I'm more detail-oriented and perfectionist, I always follow my own ideas and don't take into account other aspects. I appreciate that Beder has such an excellent mold design team.