MGMN-G type blade with CVD coating is suitable for processing steel parts

Product Details

With the continuous deep research of material technology, the company can provide high-performance, high-strength of different specifications of various types of cemented carbide bars, cemented carbide plates, electronic specifications boards, non-standard shaped materials, cold block die, wire drawing die, powder metallurgy die, CNC blade and so on.

The beginning of the supplement is as follows:

The beginning of the supplement is as follows:

In the field of precision machining in today's manufacturing industry, tool selection and coating technology have become the key factors to improve processing efficiency and workpiece quality. With the continuous progress of materials science, tool solutions for specific materials are increasingly attracting the attention of the industry. Among them, the MGMN-G blade stands out among many cutting tools for its excellent hardness, wear resistance and good toughness. And with advanced CVD (chemical vapor deposition) coating technology, it further enhances its performance in the processing of steel parts. The purpose of this paper is to explore the perfect combination of MGMN-G blade and CVD coating, analyze how to effectively deal with the challenges in steel processing, and the positive effect of this innovative combination on improving production efficiency and reducing costs.

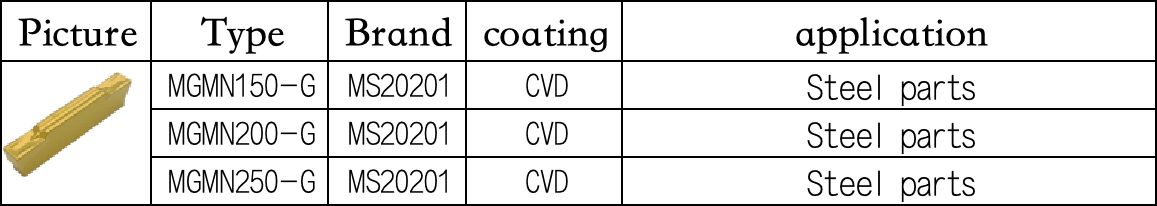

| Type | Brand | coating | application |

| MGMN150-G | MS20201 | CVD | Steel parts |

| MGMN200-G | MS20201 | CVD | Steel parts |

| MGMN250-G | MS20201 | CVD | Steel parts |

Keywords: MGMN-G type blade with CVD coating is suitable for processing steel parts