Grinding MGGN type, with 15 degree oblique mouth, excellent processing steel, stainless steel

Time:2024-10-16

### Grinding MGGN type, with 15 degree bevel, excellent processing of steel parts, stainless steel

In the field of precision manufacturing and material processing, the accuracy and efficiency of tools are directly related to the quality of products and the competitiveness of the market. Among the many cutting tools, the MGGN tool stands out with its unique design-with a 15-degree bevel, and has become a right-hand man for processing hard materials such as steel and stainless steel. This article will explore the excellent performance of MGGN tools, application scenarios and its significant advantages in improving processing efficiency and quality.

#### Introduction: Precision Manufacturing Needs and Challenges

With the advent of the era of industrial 4.0, the manufacturing industry has increasingly stringent requirements for processing accuracy, especially in high-end manufacturing fields such as automobiles, aerospace, and medical devices. The material, size, and surface quality of parts have extremely high standards. Steel and stainless steel, as common engineering materials, are widely used because of their high strength, corrosion resistance and other characteristics, but they also bring no small challenges to processing. When processing these materials, traditional tools often face problems such as fast wear, low efficiency, and unstable processing quality.

#### Unique design of MGGN tool

It is in this context, MGGN tool came into being. Its most striking feature is the elaborate 15-degree bevel. This innovative design not only optimizes the cutting angle of the tool, but also greatly improves the stability and smoothness of the cutting process. The bevel design can guide the cutting force to be more evenly distributed on the blade, reduce local stress concentration, thereby extending the service life of the tool and reducing the processing cost caused by tool wear.

#### Excellent ability to process steel parts

For steel parts, the MGGN type tool exhibits extraordinary machining capabilities. Its high hardness, high wear resistance material selection, so that the tool in the high-speed cutting process still maintain a sharp edge, effectively reduce the cutting force, reduce the impact of cutting heat on the workpiece, to ensure the surface finish and dimensional accuracy. At the same time, the bevel design makes the chips easier to discharge, avoids the tool blockage and workpiece scratches caused by chip accumulation, and further improves the processing efficiency and quality.

#### A sharp tool for stainless steel processing

In the face of stainless steel, a difficult material, MGGN tools also perform well. Due to the high hardness and good toughness of stainless steel, the traditional cutting tools are prone to sticking and chipping during processing. The MGGN tool with its unique coating technology and optimized geometry, effectively solve these problems. The coating technology improves the oxidation resistance and wear resistance of the tool, and maintains stable cutting performance even in high temperature environments; while the optimized geometry makes the cutting process more stable, reduces the generation of cutting force and vibration, and ensures The quality of the machined surface and the durability of the tool.

#### Application Scenario and Case Sharing

MGGN cutting tools are widely used in automobile manufacturing, aerospace, precision molds, medical equipment and other fields. In automobile manufacturing, it is used for precision machining of key components such as engine cylinders and crankshafts to ensure the performance and reliability of the engine; in the aerospace field, it helps to manufacture high-precision, high-strength structural parts for aircraft Safety escort. In addition, in precision mold manufacturing and medical equipment processing, MGGN cutting tools have also won wide acclaim for their excellent processing performance.

#### Conclusion: Future Outlook

With the continuous development of the manufacturing industry, the demand for processing tools will become more diversified and refined. MGGN tool with its unique design, excellent performance and wide application prospects, will play a more important role in the future manufacturing field. At the same time, we also expect that with the continuous progress of material science, coating technology and intelligent manufacturing technology, MGGN tools can be continuously upgraded and contribute more to the transformation and upgrading of the manufacturing industry. In the pursuit of higher precision, higher efficiency, lower cost on the road, MGGN tool is undoubtedly our trusted partner.

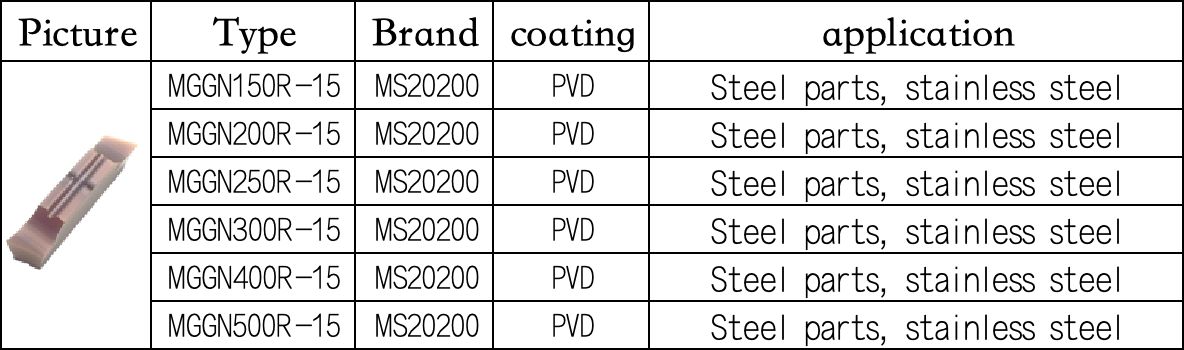

| Type | Brand | coating | application |

| MGGN150R-15 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN200R-15 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN250R-15 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN300R-15 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN400R-15 | MS20200 | PVD | Steel parts, stainless steel |

| MGGN500R-15 | MS20200 | PVD | Steel parts, stainless steel |

Keywords: Grinding MGGN type, with 15 degree oblique mouth, excellent processing steel, stainless steel

Related Cases

-

Lianxiang's professionalism is well-known

An excellent enterprise can give customers a good experience regardless of pre-sale, sale, and after-sale. Lianxiang is like this, which can not only help target customers design excellent mold solutions, but also actively cooperate with the sale, not to mention after-sales service. The service attitude is consistent, praise one!

-

Lianxiang's degree of cooperation is high, and I am very relieved

In the industry, Lianxiang has a strong production scale capacity, a large inventory of raw materials, a high degree of cooperation with customers, and can actively cooperate in the formulated production cycle to ensure on-time delivery, which I appreciate very much, and will continue to cooperate in the future.

-

Lianxiang has the ability to design independently, which I appreciate

Chengdu Lianxiang can not only provide OEM production services according to customer requirements, but also provide design concepts according to the characteristics of our company's products, which makes me feel very relieved. Because I'm more detail-oriented and perfectionist, I always follow my own ideas and don't take into account other aspects. I appreciate that Beder has such an excellent mold design team.