Grooving cutting blades, MGMN-T, machining high hard steel

Product Details

With the continuous deep research of material technology, the company can provide high-performance, high-strength of different specifications of various types of cemented carbide bars, cemented carbide plates, electronic specifications boards, non-standard shaped materials, cold block die, wire drawing die, powder metallurgy die, CNC blade and so on.

In the field of modern precision manufacturing, in the face of increasingly complex and high-strength processing requirements, the selection of appropriate cutting tools has become the key to improve production efficiency and processing quality. Especially for difficult-to-process materials such as high-hard steel, traditional blades are often difficult to meet their harsh processing conditions, easy to wear and inefficient. To this end, we have specially introduced the MGMN-T series cutting groove cutting blade, specially designed to solve the problem of high hard steel processing. The blade has attracted wide attention in the industry for its excellent cutting performance, excellent wear resistance and stable processing performance. This paper will deeply discuss the technical characteristics, application advantages and specific performance of MGMN-T cutting cutting blade in the process of processing high hard steel, so as to provide valuable reference for relevant industry practitioners.

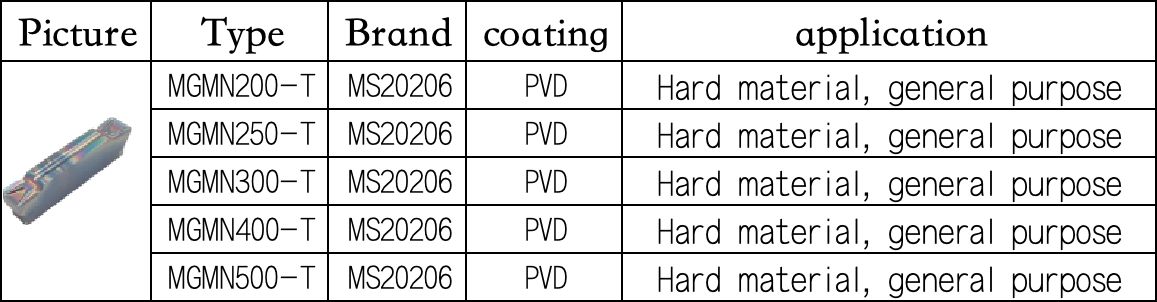

| Type | Brand | coating | application |

| MGMN200-T | MS20206 | PVD | Hard material, general purpose |

| MGMN250-T | MS20206 | PVD | Hard material, general purpose |

| MGMN300-T | MS20206 | PVD | Hard material, general purpose |

| MGMN400-T | MS20206 | PVD | Hard material, general purpose |

| MGMN500-T | MS20206 | PVD | Hard material, general purpose |

Keywords: Grooving cutting blades, MGMN-T, machining high hard steel